Toilet 'vintage' cistern with old ball-cock and valve

This all started about three and a half years ago, when we first purchased the house, the first DIY job I had was to fix the dripping overflow from the toilet in the bathroom. The toilet cistern is rather narrow, and possibly vintage (or old) because it contains a very large porcelain flush, the disadvantage of this is, there is not much room in the cistern for a replacement ball cock and valve.

After searching in various DIY stores, I couldn’t find replacement part that would fit the cistern, so I just “modified” the brass ball cock arm by bending it slightly to stop the dripping overlow.

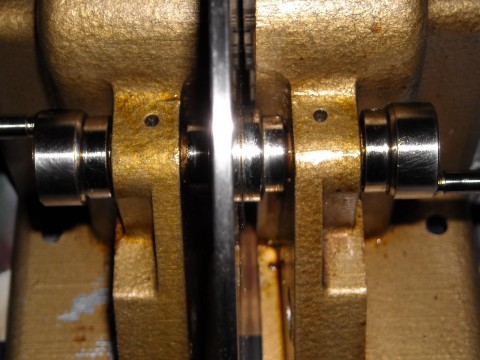

close-up of old ball-cock and valve

Many months later, I found some replacement brass fittings, so I purchased three of them, and stored them in the garage until it needed replacing for good.

New brass ball cock valve

Well this DIY bodge job came back to haunt me, because it started dripping again a few months ago. So it was time to replace with the parts in stock in the garage.

New part fitted

The only problem with the new ball cock and valve fitted, was the shaft was too short, and I couldn’t fit the ball cock to it. Back to the drawing board, so I removed the old shaft, and connected it to the new valve. This worked and stopped the dripping valve, but when the toilet cistern filled, it was horrendously noisy! I later discovered it was the venturi action of the valve that was causing the noise under high pressure. So back to the drawing board and Google. I then discovered Fluidmaster a quiet fill small footprint fill valve, but there isn’t much room in the cistern, so off to Screwfix for the part.

Fluidmaster Quiet Float Valve

When was the last plumbing part your purchased, comes in a nice box? with instructions on the back of the box, and an A4 sheet inside!

It didn’t take me very long to fit this new Fluidmaster part, and there was just enough space, a few millimetres clearance from the flush mechanism and walls of the cistern, must make sure there’s enough clearance, and regularly check or will have another flood!

Oh yes the flood, following the instructions, Step 7. IMPORTANT ALWAYS CLEAR ANY DEBRIS FROM WATER LINE TO COMPLETE INSTALLATION. So I shut off the water as instructed, removed the cap, went downstairs, and under the kitchen sink, turn-ed back on the water…… oh #@!? when I returned to the bathroom, water under extreme pressure was hitting the opposite end of the cistern, and water was then travelling vertically, and hitting the ceiling, and then dripping off, I had to run back downstairs and turn off the water! I think it would have been best if the instructions had stated to place the top back on the cistern!

The bathroom was flooded!!! (didn’t have time to take pictures, mopping up the water!).

Anyway pictures of the Fluidmaster installed…

Quiet Float Valve by Fluidmaster

Quiet Float Valve by Fluidmaster

Quiet Float Valve by Fluidmaster

It does what it says on the tin or box in this case, it’s quiet! So no more nosiy toilet! (when it’s filling anyway!).

![Validate my RSS feed [Valid RSS]](http://andysworld.org.uk/images/valid-rss.png)